litho printing vs Digital Printing: What to Understand

litho printing vs Digital Printing: What to Understand

Blog Article

A Comprehensive Guide to Comprehending Litho Printing Strategies

The world of litho printing, a strategy stemming from the late 18th century, is an interesting blend of background, science, technology and art. This thorough guide will certainly unwind the intricacies of this printing approach, from the structure of litho inks to the difficulties encountered in contemporary applications. As we venture into the details of lithography, the value of automation and sustainability in guaranteeing its future significance ends up being significantly clear. Stay with us as we trip into the captivating world of litho printing.

The Historic Advancement of Litho Printing

The historic trajectory of litho printing, an essential technology in the world of interaction, is a fascinating tale of human ingenuity. The procedure progressed with the arrival of the rotating press, which greatly increased productivity. Each phase of litho printing's development showcases humankind's unrelenting search of performance and high quality in aesthetic communication.

Deciphering the Scientific Research Behind Litho Printing Inks

Moving onward in the expedition of litho printing methods, the focus now changes to the scientific research behind litho printing inks. The structure of these inks, their drying out procedure, and shade mixing methods develop the backbone of this intricate art type. Comprehending these elements is critical to mastering the craft and attaining the desired print results.

Composition of Litho Inks

In lithographic printing, the basic role of litho inks can not be overemphasized. Pigments, the color-providing components, are carefully ground particles suspended in the car, a fluid that brings the pigment onto the printing surface. Each part plays an important component in the final print's high quality, making the specific formula of litho inks an elaborate scientific research.

Ink Drying Process

From the make-up of litho inks, focus transforms to the remarkable process of ink drying. The drying process is important, as it affects the final print's top quality and long life. 2 key techniques are made use of in litho printing: oxidative drying out and absorption. Oxidative drying involves the ink responding with oxygen in the air to develop a hard, dry film. This method provides a durable coating, yet can be slower compared to absorption. Absorption, on the various other hand, involves the ink permeating into the paper fibers, which is a faster procedure but can result in much less vivid shades. The choice in between these techniques is dependent upon elements such as print speed needs, the paper type utilized, and the preferred coating.

Shade Combining Techniques

While the drying process plays a key role in litho printing, the scientific research of color blending techniques holds equal significance. The scientific research behind litho printing inks likewise takes right into account the transparency of the ink, which affects just how colors overlay and mix.

The Art and Style Elements in Litho Printing

Litho printing takes a breath life into art and design through its unique elements. Litho printing suits a range of shades, enabling artists to develop vivid and vibrant prints. This combination of precision and versatility makes litho printing a favored choice for numerous artists and designers.

Modern Applications of Litho Printing Techniques

Litho printing methods have discovered substantial usage in the contemporary commercial market. Its impact and value read here continue to expand with the development of new developments and innovations in the field. This section will certainly explore these modern applications and the transformative function they play in the printing market.

Industrial Litho Printing Uses

In today's digital age, one could question about the importance of traditional printing methods. Yet, litho printing remains a vital component of the business field. High-volume printing tasks, such as the manufacturing of books, newspapers, and packaging, count on litho printing for its capability to deliver premium picture quality and expense effectiveness. The procedure, which entails moving this link an inked photo from a plate onto a rubber covering and after that to the printing surface, provides unmatched consistency. This makes it excellent for jobs needing a big print run. Litho printing likewise provides a broad shade range, above that of digital printing. This makes it the best choice for projects that require vivid, high-grade shade recreation.

Technologies in Litho Printing

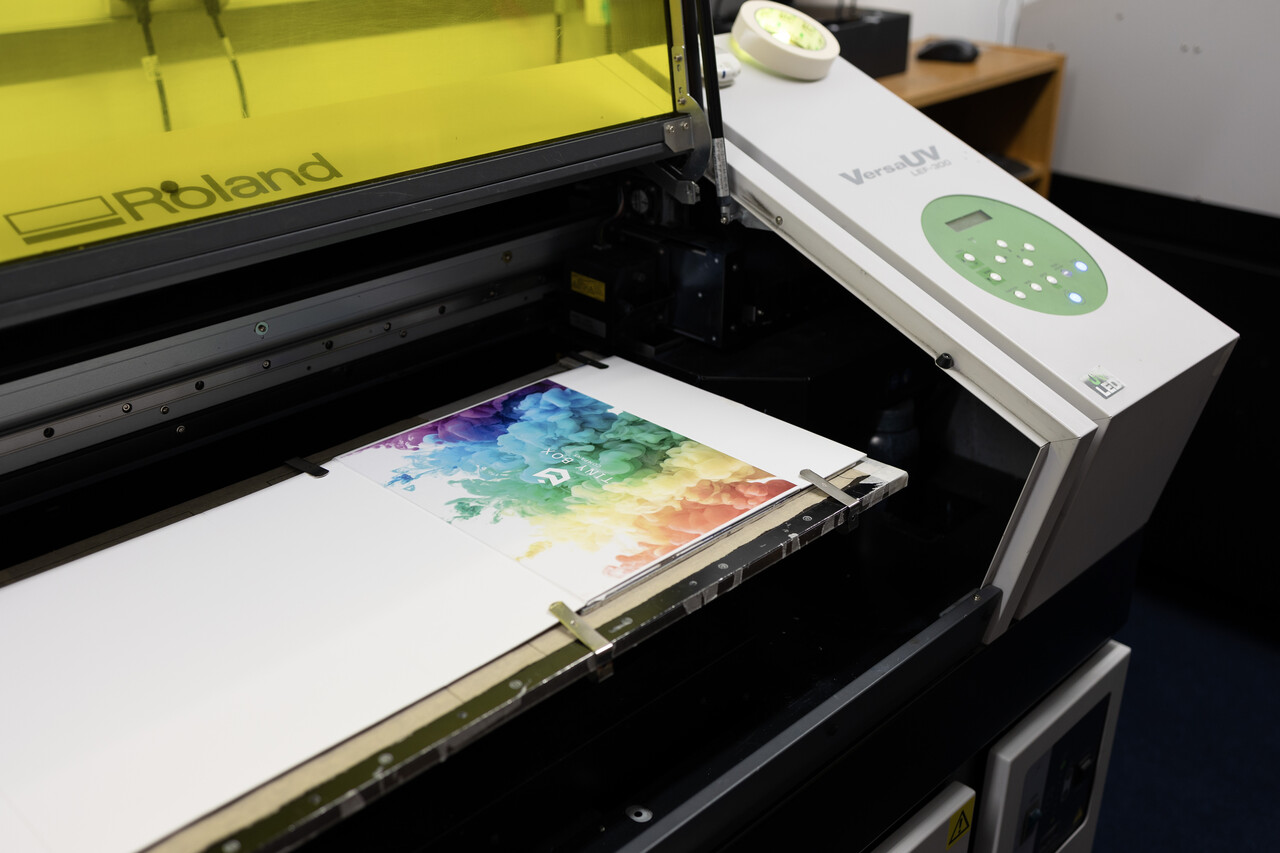

Pressing the limits of conventional strategies, modern advancements have actually fueled a host of developments in litho printing. These breakthroughs have not only boosted the high quality and efficiency of litho prints but likewise broadened its application range. One prominent growth is electronic litho printing, which integrates the virtues of digital modern technology with litho's high-quality result. This crossbreed version offers faster setup times, decreased waste, and makes it possible for on-demand printing. One more noteworthy innovation is the introduction of eco-friendly inks. These inks, made from vegetable or soy-based options, have dramatically reduced the market's ecological influence. litho printing. In addition, the development of innovative plate modern technology has structured the printing process, causing sharper photos and enhanced color integrity. These innovations emphasize the long-lasting importance of litho printing in the contemporary world.

Exploring the Process of Litho Printing: Action by Action

Challenges and Solutions in Contemporary Litho Printing

Regardless of the precision and practice that litho printing proudly maintains, it is not without its collection of modern challenges. Digital litho printing allows for economical short runs and easy customization, dealing with the concern of variable information. Thus, while there are difficulties, the litho printing industry is proactively adjusting to satisfy them head-on, ensuring its significance in the future.

Conclusion

To conclude, litho printing, with its rich background and clinical ins and outs, holds a significant area in the print sector. As the overview discloses, it's a synthesis of art and technology, with modern improvements guaranteeing its significance. Nonetheless, the market deals with challenges that call for ingenious options, with a concentrate on automation and sustainability. The future of litho printing depends upon its capability to adapt to these transforming demands, affirming its enduring value in an evolving market.

Report this page